THE BEST CHOICE FOR YOUR INDUSTRY

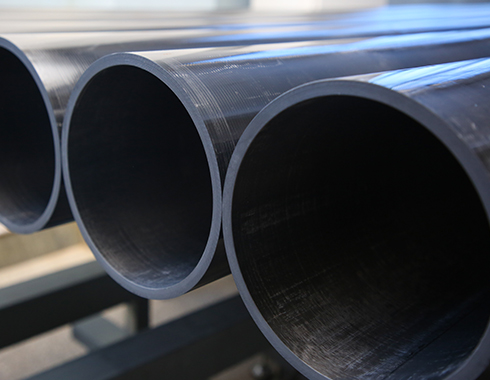

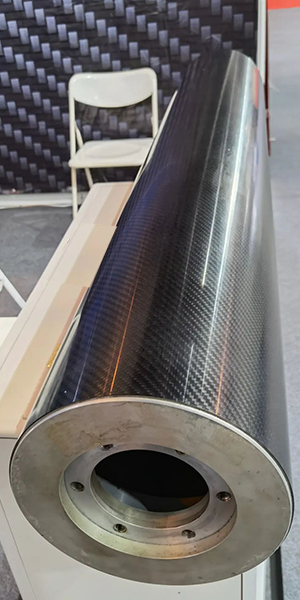

After more than ten years of development and accumulation, we have been focusing on manufacturing advanced composite tubing, which can provide large diameters and extremely long lengths. Every day we meet customers from different industrial, asking about the application of carbon fiber tubing, our enthusiasm and professionalism can always provide them with new ideas and implement them effectively.Contact us to see what we can do for you.

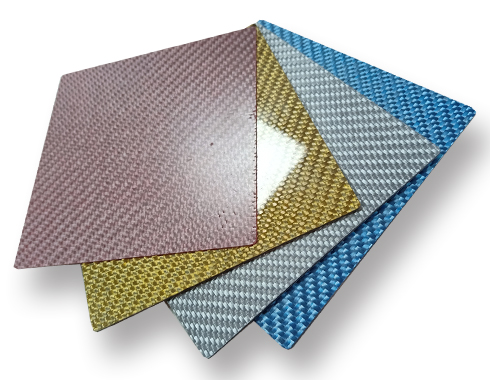

PRODUCTS SPECIFICATION

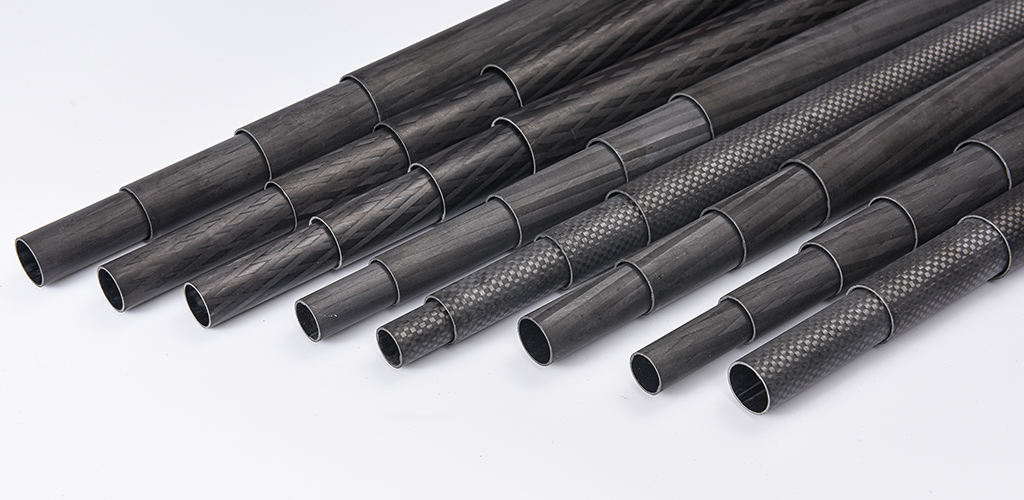

| NO | Type | ID | Thickness | Length | ID Tolerance | OD Tolerance | Pattern | Finish | Logo |

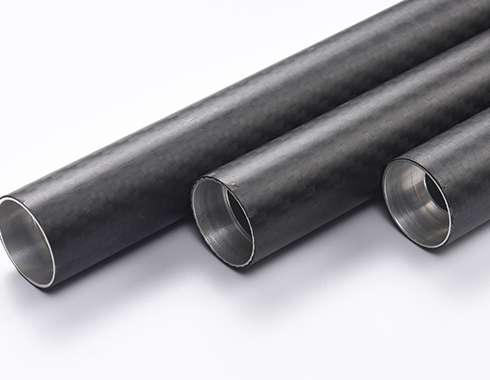

| 1 | Roll Wrapped Tubes | 0.039″-21.65″ | 0.047“-0.098” | Max 393.70“ | +0.0019″/0 | ±0.0019″ | 3K Twill, 3K Plain, Single Twill, Braided Twill, UD Solid, New Football, Hexagon Honeycomb etc. | Gloss Matte Wax Coating | Custom Logo, Low MOQ. |

| 2 | Filament Winding Tubes | 0.3937″-3.149″ | 0.059″-0.157″ | Max 39.37″ | ±0.0039″ | ±0.0059″ | Filament Winding | ||

| 3 | Pultruded Winding Tubes | 0.591″-1.575″ | 0.047″-0.059″ | Unlimited | ±0.0039″ | ±0.0059″ | Pultruded Winding | ||

| 4 | Rectangular Tubes | 0.3937″-3.149″ | 0.039″-0.157″ | Max 39.37″ | ±0.0019″ | ±0.0019″ | 3K Twill, 3K Plain, Single Twill, UD Solid, | ||

| 5 | Telescopic Tubes | 0.236″-1.575″ | 0.019″-0.118″ | Max 39.37″ | +0.0019″/0 | ±0.0019″ | 3K Twill, 3K Plain, Single Twill, UD Solid, | Wax Coating |

ENGINEERING AND DESIGN

We are an integrated solutions composite engineering company, we have assisted many customers get their products from concept to reality. From custom end fittings and connections to structural laminate design and stress analysis, our staff can help you come up with a functional design for whatever your product is. Release you from a heavy engineering work.

CAPABILITIES

We use different processes to make carbon fiber tubing according to different customer requirements and application products. From the initial process selection to the later fine processing, we can fully meet the requirements of customers. For example, the accuracy of our inner diameter and outer diameter can best reach 0.0019″, the maximum outer diameter can reach 21.65″, and the length can be infinite. According to different laminate structures, excellent bending, compression and torque properties can be obtained.

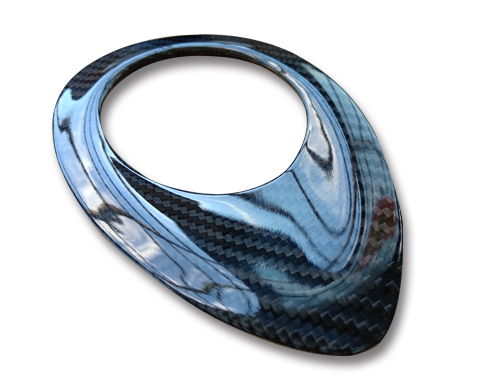

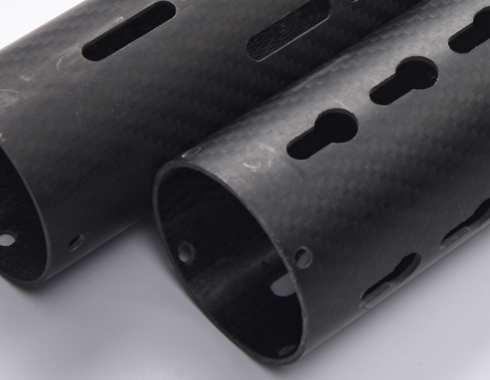

Machining and Assembly

We have an independent CNC machine workshop dedicated to processing carbon fiber tubes and carbon fiber sheets. Some carbon fiber tubes need to be carefully processed to be assembled with other accessories. According to different requirements, we will process and treat the surface of our bare tube or blank tube to facilitate subsequent bonding and assembly.

STOCK TUBING

In rare cases, we will stock certain specifications of carbon fiber tubing for emergency use. Because there are so many options for tubing sizes and thicknesses, we do not stock all specifications. After more than ten years of accumulation, we have kept most of the molds with different specifications. Even if we don’t have ready-made molds, it only takes about a week to re-customize a mold, so don’t be afraid to ask us, there is always a size that meets your requirements.

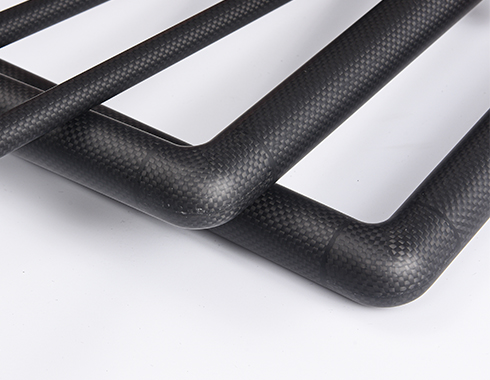

BARE TUBING TO FINISHED PRODUCTS

In addition to unfinished / bare carbon fiber tubing, we can also provide many other post manufacturing services.

- Sanding

- Painting / coating

- OD turning

- Cutting

- Milling

- Drilling

- Chamfering

- Centerless grinding

- Machining

- Hardware installation (end fittings, hardware, etc)

- Assembly

APPLICATIONS

Our tubing has been used in a wide range of applications.

- surveillance blimp

- axle

- probing and sensor equipment

- golf shaft

- conveyor belt roller

- kite and aircraft wing spar

- guitar neck and push rod

- Light Aircraft

- Radar and GPS antennas

- Stiffening and reinforcing beams

- Autonomous craft

- Unmanned vehicle capture booms

- Underwater equipment

- Telescope housing

- Large telescope truss tubing

- Robotic arms

- Transport beams

- Mining equipment

- Performance arts and production

- Oil and Gas down-hole applications

- Security gates

- Medical equipment

- Yatch masts