Composites Manuacturing:

How Azure Teams Manufacture Your Projects

Composites manufacturing preperation

Composites manufacturing is the main work of Azure currently runs, we are a supplier with more than 15 years of experience on manufacturing carbon fiber parts. A good start is half the battle. Let’s get the following info before proceeding the project:

- 2D drawings or 3D drawings or prototypes

- Length*Width*Height*Thickness

- Materials

- Patterns

- Finish

- Logo applied

- Tolerance

- Test request

- Quantity

Want to make it easier? Click here.

Best carbon fiber technologies

Azure chooses the heated moulded to meet customers’ requirements for high quality and large capacity. Our heated moulded process features:

- High premium surface finish and excellent quality.

- Semi automatic operation to double the production capacity.

- High accuracy.

- The operating environment is clean and environmental friendly.

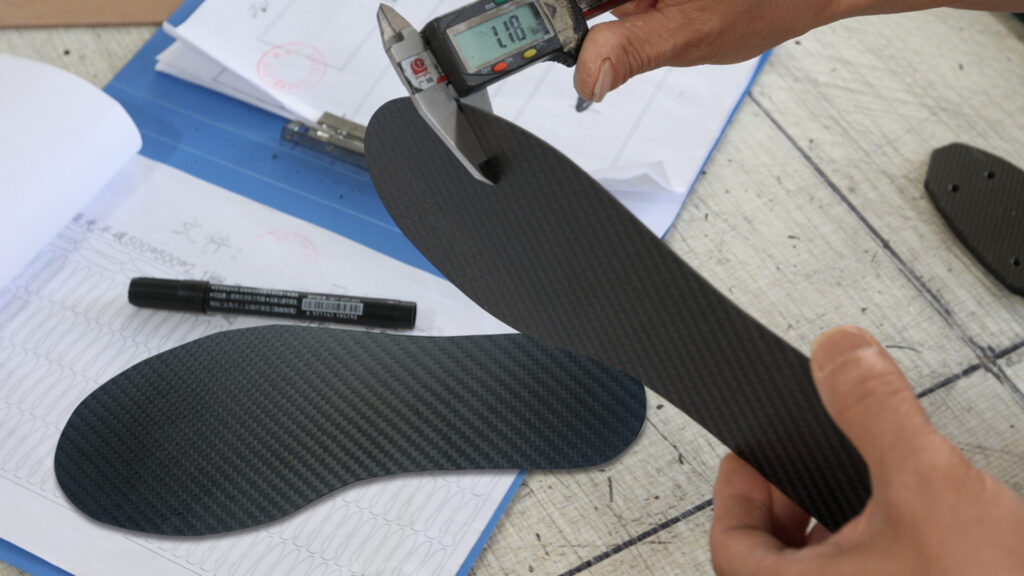

It is very suitable for products with large quantity and high surface requirements like carbon fiber sheets, carbon fiber insoles, carbon fiber soles, hexagon carbon fiber tubes, square tubes,carbon fibre taper, etc.

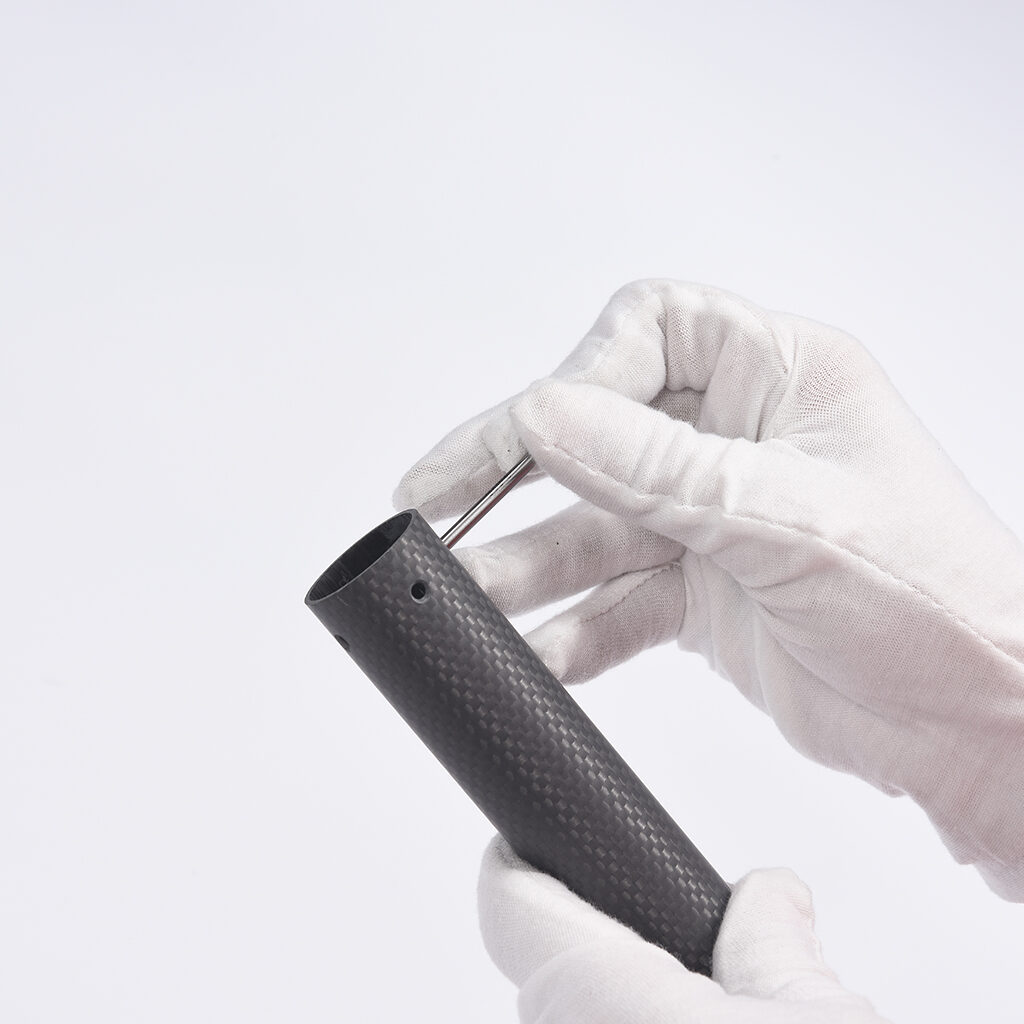

The bladder moulded(air bag moulded) process is a kind of molding process. If the carbon fiber product is hollow internally and requests a unique shape, Azure team will analyze and adopt the bladder molding process. The bladder molding process can not only ensure the smooth appearance of the product, but also ensure the internal smoothness and the consistency of the overall thickness. We use this process to make carbon fiber helmets, carbon fiber shaft knobs, carbon fiber frame for bicycles, carbon fiber hockey clubs, etc.

Due to the excellent performance of carbon fiber, many large-sized products are also considered to be manufactured by autoclave process. What are the advantages of autoclave technology? The Azure team(Azure is carbon fiber products manufacturer) told us that we can produce with autoclaves of different sizes according to the size of the product. The limit size of our autoclave is to be able to produce products with a length of 4.8m and a width of 2.3m, or to produce multiple small-scale products at the same time, which saves energy. The products produced by autoclave process can ensure the smooth surface of carbon fiber and the consistency of internal smoothness and thickness. For the production of mold cost control is also a major advantage. We generally use this process in carbon fiber surfboards, carbon fiber helmets, carbon fiber auto parts, etc.

We have 3-axis to 5-axis CNC processing machines, which can be used for the processing of various composites manufacturing and the precise processing of custom complex carbon fiber products with different shapes to meet the needs of different customers and products.

Azure has more than 5 carbon fiber pipe rolling wrapped machines, which can quickly and low-cost produce carbon fiber pipes of various sizes and specifications, including different patterns and colors, such as 3K plain, 3K twill, braided, football, airplane and other jacquard carbon fiber patterns, grooved carbon fiber posts and convex grooved carbon fiber pipes. The tolerance should preferably reach+/-0.1mm, the longest round pipe can reach 10m, and the maximum diameter can reach 550mm. Azure composites products co., ltd. recommends to proceed this technical to various specifications of carbon fiber telescopic tubes, carbon fiber vacuum cleaner pipe, carbon fiber masts, geothermal carbon fiber pipes, etc.

Filament winding process is one of the important processing methods of Azure. As carbon fiber filament wound can improve the consistence of strength of products, and has better cost control on production, it can realize semi-automatic or full automation, its quality is stable, and its efficiency is high. It has become the first choice for manufacturing Azure composite products, carbon fiber pipes and carbon fiber hydrogen vessel in type IV, and it is suitable for mass production. For more information, please contact Azure.

Pultruded winding is a combined process of pultrusion and filament winding. It is mainly used for the production of composites pipes with unlimited length. It can realize the full automatic production of carbon fiber pipes with very high production efficiency. Carbon fiber tubes produced by pultruded winding have outstanding specific strength and specific stiffness. Azure suggests our customers to use this process to produce a large number of low-cost and high-quality carbon fiber tubes.

Azure is a professional manufacturer of carbon fiber products. Our factory has our own painting workshop, which can provide customers with one-stop carbon fiber product solutions. As high-end products, carbon fiber products have strict requirements on the surface. From the perspective of surface effect, we choose gloss finish, matte finish or semi matte finish paint. From the perspective of function, we can increase the UV protection function to increase the product’s ability to maintain excellent performance in extreme environments for a longer time. Azure’s paint shop can also add customized logo, signature or designs according to different requirements of different customers to produce unique carbon fiber products for you, such as carbon fiber masks with their own signatures and logo who the top footballers wears in FIFA World Cup.

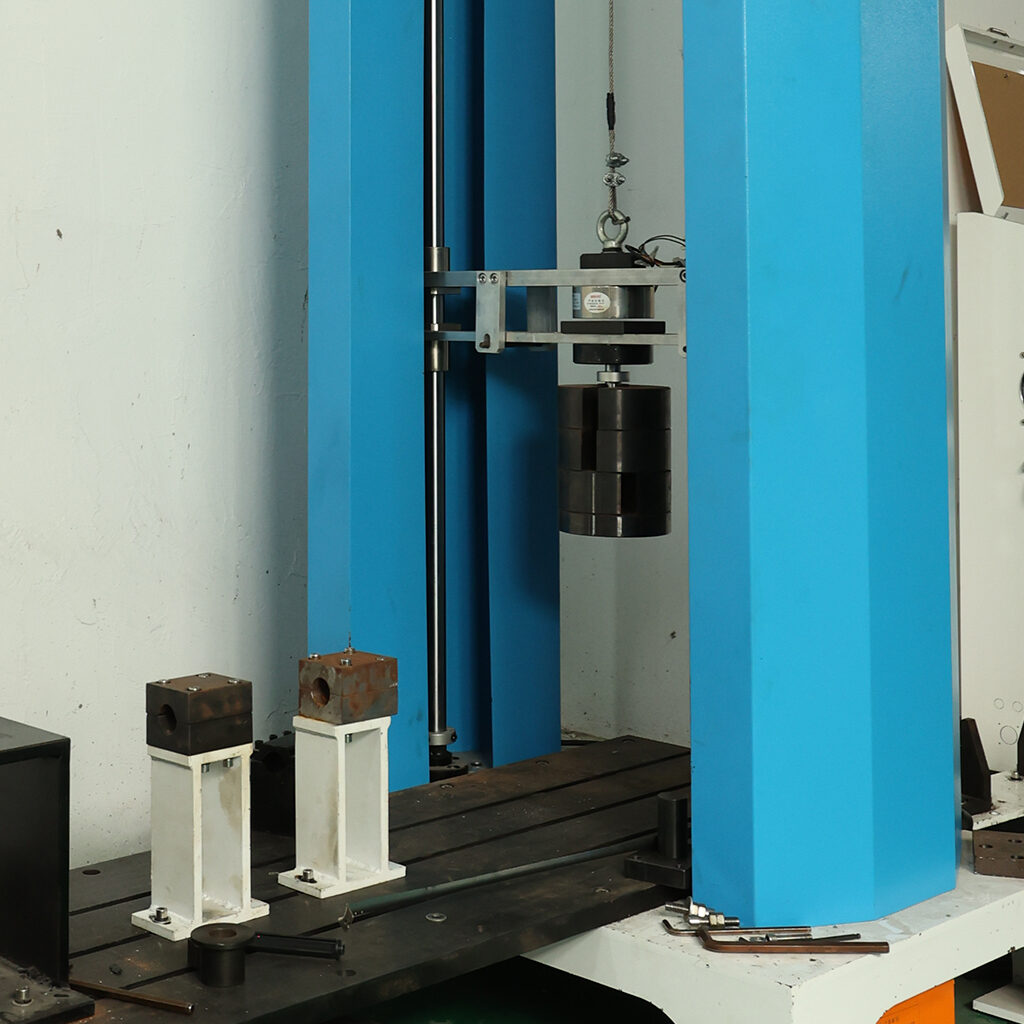

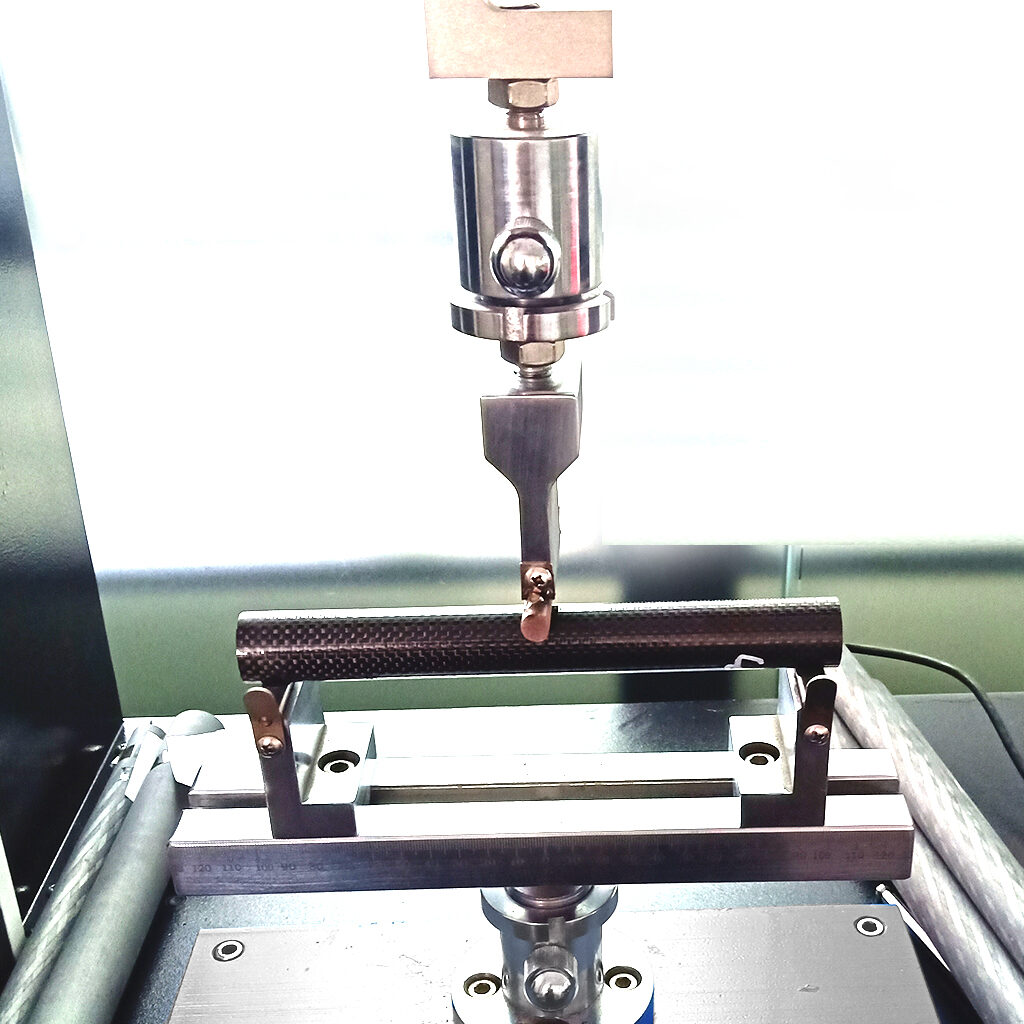

Professional and strict quality check

Azure not only provides the best technical support, but also ensures that the final products are of high quality, and always strives to provide customers with the best quality products. Our own quality control department uses various existing modern and advanced testing instruments and jigs to deliver qualified high-quality carbon fiber products to customers. Providing quality services and premium quality products has always been our goal.

Test equipment

For carbon fiber products with physical performance requirements, in addition to regular QC check, Azure is not only using the advanced composites manufacturing but also carry out necessary physical tests for products according to different requirements of customers. We have complete testing equipment to ensure that our products meet all requirements of customers:

- Loading test

- Impact test

- Dynamic fatigue test

- Twist fatigue test

- More will be coming soon...

we will assist you 24/7

Quick Contact

- 3K carbon fiber sheets

- Solid carbon fiber sheets

- Forged carbon fiber sheets

- Marble carbon fiber sheets

- CNC carbon fiber sheets

- Colored carbon fiber sheets

- Roll wrapped

- Filament winding

- Pulltruded winding

- Square carbon fiber tubes

- Extra large carbon fiber tubes

- Colored carbon fiber tubes

- Battery casing

- Handling bars

- Carbon fiber insoles

- Car window bezels

- X-Ray pannels

- 3 ways connectors